The most sensitive yet important part of your boat is the boat floor. Why? Because it has direct exposure to the water which makes it wear and tear. Hence, you might need to replace it after a certain time.

So, you might be wondering about how to replace the boat floor.

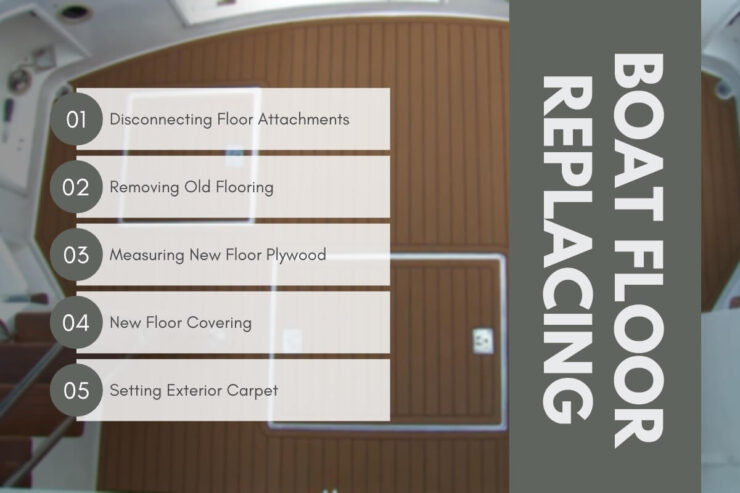

Well, replacing boat flooring requires five easier steps. Firstly you have to detach the floor materials and then remove the old flooring. After that measure the plywood for new flooring and place it. Finally, cover the flooring with carpet and an external fiber mat with the help of resin.

So if you are willing to know more details about it, this entire article is for you to enlighten you with that.

Let’s not make any delay and jump right into it.

Table of Contents

ToggleBoat Floor Replacing: Floor Material Options

It’s always the type of boat you own that will decide about its material of it. However, there is a wide range of options for you as well. For example, fiber cement board, fiberboard, thermo-lite board, etc.

The best part is if you choose good quality flooring, you will be good to go for years. If you ask us what would be the best options then some of the suggestions would be

- Aluminum flooring

- Marine carpet flooring

- PVC tile flooring

- Rubber marine flooring

- Canvas Flooring

- Vinyl marine flooring

- Wooden Flooring

These are the common and effective flooring options for your boat.

Instruments/Tools You Need

Changing the flooring of the boat is a long and stepwise process. To follow those you will be needing some tools. These are-

- Plywood

- Carpet or floor covering

- Power drill

- Epoxy

- Fiberglass mat

- Circular saw

You will definitely be finding these tools useful while replacing your boat floor.

Boat Floor Replacing: in 5 Steps

If you find your floor soggy and spongy then it is the indicator for replacing the floor. One thing you need to keep in mind is boat floor replacement wouldn’t damage your boat. In fact, it would make your boat sustainable and long-lasting.

The process of replacing the boat floor is not that difficult. You can easily conduct it on your own by following the steps accordingly. Here we are discussing every step with precise details.

So if you are interested in it, the following segment is important for you-

Step 1: Disconnecting Floor Attachments

Remove the old seats, pillars, carpets, or any other stuff which is connected to the old floor. Make sure you have removed all the wearing and every connection which is directly attached to the floor.

Step 2: Removing Old Flooring

Now it’s time for removing the old flooring from the boat. It is very important to keep the old flooring intact. As it will help you to get the perfect measurement for the new one.

It will also guide you to make the perfect screw holes for deck resemblance. Leave at least 3 to 4 inches of trim all around the edge of the old floor. It will protect the sides of your boat from damage.

And the most important role of this is to support the new floor. It will work as a mold of the newer floor and support it.

Step 3: Measuring New Floor Plywood

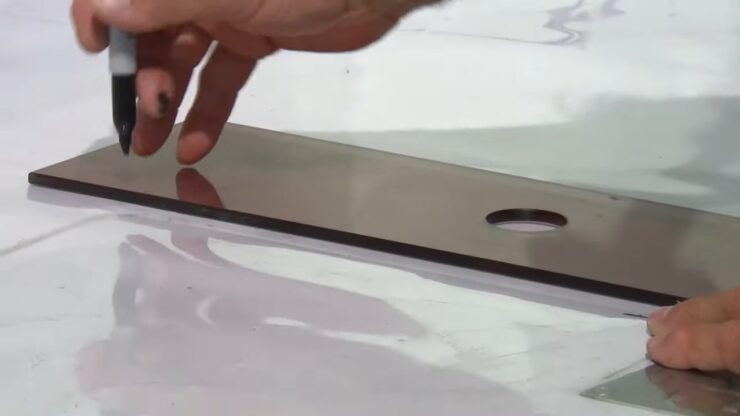

Now it’s time for measuring the new piece of plywood. The best way would be to use the old template or flooring. Now soak the measured pieces with epoxy.

It will help you to seal the water out of the board. After drying the epoxy out, you can start screwing it in place.

Screw hole placement and measurement are very important here. Try to follow the older floor for that. Make sure the screw holes are accurate with perfect diameters.

Step 4: New Floor Covering

It’s time for covering the new flooring with a fiberglass mat. You have to seal it with the floor using fiberglass resin. And after the resin dried you have too uneven edges.

You can smooth the edges with a soft sender. Now drill screw holes in the fiberglass mat.

Step 5: Setting Exterior Carpet

We are almost done with our setting. Now you can set the exterior carpet. And now you can set all the seats and other wires and fittings. Also, you can set the items on the deck.

Sometimes people also face boat throttle cable problems.

Mistakes to Avoid While Replacing Boat Floor

There are some common mistakes people make while replacing a boat floor. We don’t want you to repeat it. That’s why we are mentioning the most common mistakes in the following.

- Never use nails for the boat floor. It makes the floor weakens the boat structure. Thus you are damaging the longevity of the boat.

- Avoid using the wrong material. It is very important to choose a suitable material for your boat. Otherwise, it might not stay as long as it is expected. You might face some other issues too.

- Finally, Don’t forget to resolve the rot. Your boat floor might rot due to moisture and exposure to water. So if you figure out any rot just scrub it out right away. Otherwise, there is a high chance of it damaging your boat permanently.

Stratos boat problem is another common problem you might face other than flooring problems.

How to fit a boat floor?

Fitting a boat floor is not as difficult as it may seem at first. With a little time and effort, you can have a new, custom-fit floor in no time!

Here are the basics of how to fit a boat floor:

1. Measure the area where the new floor will go. This will give you an idea of what size and shape of flooring you’ll need to buy.

2. Cut the new flooring to size, using a sharp knife or power saw. Make sure all the pieces fit together snugly before proceeding to the next step.

3. Install any hardware that will be needed to secure the new flooring in place. This may include screws, nails, or adhesive strips.

4. Place the new flooring in position and secure it in place. You may need to use clamps or weights to keep everything in place while the adhesive dries.

5. Allow the adhesive to dry completely before walking on or using the newly fitted floor.

How to waterproof plywood boat floor?

One way to waterproof plywood boat floors is to use a sealant. This can be applied with a brush or roller and will create a barrier between the wood and the water. Sealants come in both clear and tinted varieties, so you can choose the look that you want for your boat.

Another option for waterproofing plywood boat floors is to use a coating that is applied like paint. Coatings are available in both clear and tinted varieties, so you can again choose the look that you want for your boat.

FAQs

What is the best type of wood for boar flooring?

Among several options, oak wood is the most suitable one for boat flooring. Oak woods are budget-friendly and sustainable. It will provide rot resistance along with the strength of your boat flooring. Marine plywood is another great option for boat flooring. It is easy to customize with basic tools.

What should be the ideal thickness of the boat floor?

Proper thickness plays a vital role in boat flooring. For good flooring, ¾ is good enough. You can go for ½ or ¾ according to your boat and preference. Just make sure you are choosing a good material for your boat. Thus you can ensure long-lasting flooring.

How long usually does a boat flooring last?

You will be surprised to know that a boat’s floor lifespan is around ten to twenty years. In fact, some boats last longer than that. But mostly the lifespan depends on how you are treating your boat. which means how are you using your boat. Also how you are doing maintenance with time.

How thick should plywood be on the boat floor?

It is important to choose a thickness that is appropriate for the type of boat you have and the conditions it will be used in.

The thickness of plywood used for the boat floor should be from 1/2 to 5/8 inches. Anything thinner than that is too weak and will not provide enough support, especially for larger boats.

How many layers of fiberglass do you need for a boat floor?

The answer will depend on the thickness of the fiberglass cloth that you are using and the desired thickness of the finished floor.

For example, if you are using a 6 oz. fiberglass cloth and you want a finished floor that is 1/4″ thick, you will need 4 layers of fiberglass. If you are using an 8 oz. fiberglass cloth and you want a finished floor that is 1/2″ thick, you will need 8 layers of fiberglass.

The number of layers of fiberglass needed can also be affected by the type of resin used. For instance, if you are using polyester resin, it will take more layers to achieve the same thickness as with epoxy resin.

Final Words

We hope we could solve all your queries regarding how to replace the boat floor. If you are concerned about your boat floor make sure you choose the right flooring material.

One extra tip for you, make sure your boat is getting proper maintenance with time. That will increase the lifespan of your boat.

See you soon with some other interesting topics. Till then have a great time!

I’m Liam Jackson, the proud owner and driving force behind KayakPaddling.net. Born somewhere in the expansive beauty of the United States, I’ve nurtured a lifelong passion for kayaking and fishing that has led me to explore the far corners of our nation’s waterways.

Related Posts:

- 16 Best Kayak For Beginners 2024 - Kayaking Adventure Gear

- Heavy Duty Fishing: 11 Best Rods And Reels For Big Fish 2024

- Replace the Boat Carpet With a Non-slip One - Best Options

- 10 Best Saltwater Fishing Boats - Ultimate Angling Adventure

- 12 Best Bass Boats Under $20,000 2024 - Catch Your Prize

- 20 Best Inshore Spinning Reels 2024 - Capturing All…